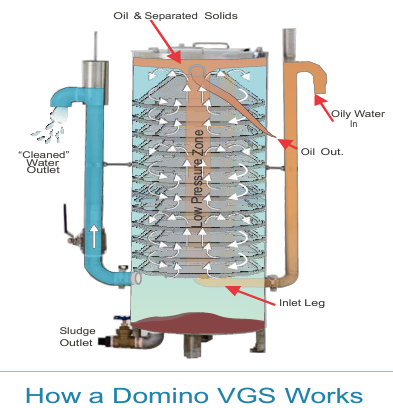

The VGS (Vertical Gravity Separator) is an oil water separator which has been developed to effectively remove free oil, grease and suspended solids from wastewater plus greatly reduce the frequency and difficulty of maintenance compared to conventional plate separators. The VGS is a flooded system in which the inlet and outlet columns form a U-tube configuration such that the oil is trapped on one side of the main body, while the cleaned water flows out of the other side.

The main body contains a continuous truncated conical spiral pack (SPAK) which is made of olephilic material. Oily water is delivered into the bottom of the main body where it flows upwards through the centre of the SPAK assembly. At the top of the main body, free oil and low density suspended solids are held, which eventually flow out for collection and suitable disposal.

Flat bottom VGS & extended body VGS oil water separator

VGS – Vertical gravity separator flow diagram

The partially cleaned water is directed to the outside perimeter of the conical SPAK and follows a tortuous pattern while cascading down and around the SPAK. Here the lower density fluid (oil) is drawn up the incline of the olephilic surface of the SPAK and back into the low pressure centre of the VGS, where it commingles with the incoming fluid and is redirected to the top of the main body.

A continuous convention is created within the SPAK by the density and pressure variation down the fluid column and the upward flow of the cleaned water will enter the output leg of the separator and will flow up and out of the system, whilst the heavy solids will drop to the base of the vessel.

The partially cleaned water is directed to the outside perimeter of the conical SPAK and follows a tortuous pattern while cascading down and around the SPAK. Here the lower density fluid (oil) is drawn up the incline of the olephilic surface of the SPAK and back into the low pressure centre of the VGS, where it commingles with the incoming fluid and is redirected to the top of the main body.

A continuous convention is created within the SPAK by the density and pressure variation down the fluid column and the upward flow of the cleaned water will enter the output leg of the separator and will flow up and out of the system, whilst the heavy solids will drop to the base of the vessel.

VGS – Vertical gravity separator flow diagram

Domino VGS oil water separator

Due to its ingenious design the Domino VGS is capable of continually meeting the performance standards set by the EPA and other regulatory authorities.

Suspended solids in Domino VGS rise with oil to waste tank; heavy solids settle at the bottom, removed via control valve.

The turbulent flow principle of the Domino VGS ensures the vapour content of the wastewater being treated is always reduced to safe levels.

Domino VGS's vertical design saves space. Unique features allow quick on-line cleaning, eliminating need for plate removal or harsh chemicals.

Versatile Solutions for Automotive Maintenance and Cleaning